Projects & Training Programs By ARROWHEAD

Session based

i. In such case project is not yet identified.

ii. We will conduct a value-stream mapping session, which maps entire flow of service/product and data within business from Order to Cash.

iii. This session lasts 2 full days.

iv. By end of 2nd day you will be able to get a list of projects which your business should focus on. These projects will be across different aspects of cost reduction, improving quality and reducing lead time.

i. This is a minimum 3d or maximum 5d event.

ii. In this event we target a certain aspect of business, e.g. – Finance, HR, Production, Sales, Warehousing and Logistics, Data/Information management, New Product Development.

iii. In this event a thorough analysis of current state, all its hurdles along with root-cause analysis and creating future state map is accomplished, to culminate into list of solutions with clear definition of how/what/why/who.

i. This is a 3d session.

ii. Over course of this session a plan of how to create an impactful lean based workplace is designed.

iii. This includes plan built around all aspects of visual, verbal and mind-based solutions of how to instil a new vigour within your work force that is wrapped around philosophy of continuous improvement.

i. Study of repeatability and reproducibility within your execution process (product or services).

ii. This is a 3d session spread across understanding current state of repeatability (ability to produce same result by same operator/employee) and reproducibility (ability to produce same result between different operators/employees)

iii. Based on this we build a Gage R-R experiment and execute this on day 2 with actual operators involved.

iv. On day 3 we will show results from this study and help create a solution of how to solve this problem. Execution can be completed by your team or we can help implement the solution too.

i. This is split into 2 sessions. Each lasting 3d. Total 6d.

ii. In Session 1 a thorough analysis of all variables impacting the consistency of output within your production process are assessed.

iii. A DOE using different variables is prioritized along with levels of study (i.e. 2 factorial or 3 factorial or more).

iv. In Session 2 the experiment is conducted post which immediate analysis of results and conclusions of how to optimize your process and which variables you should focus upon are revealed.

Specific area within business

Management may already have clear understanding of pain points within their business model in certain area. In such scenario, we will inherit thorough understanding of project and suggest and/or implement solutions using Lean and Six-Sigma concepts. Tenure of project is mutually decided based on scope of project.

Developing Overall Equipment Effectiveness:

i. Understanding your current values around OEE metrics and how to implement successful impact of OEE.

ii. Identify solutions within all 3 parameters of OEE (equipment availability, first pass yield, quality) that need to be implemented in order to have world class OEE.

iii. Engagement here can be limited to developing solutions or can go on till OEE > 90%.

Look at entire business model

In this case we start by conducting a detailed Value-Stream Mapping session that covers all steps from Order to Cash. This exercise reveals all non-value-added areas across each department around data flow and product flow (in case of services industry its mainly about data/information flow). This culminates into consensus about projects around areas of immediate and long-term focus.

Detailed Project plans are built based on the value-stream map.

Dedicated teams are set-up.

Project implementation led by ARROWHEAD using Lean Six-Sigma concepts along with frequent governance of progress with team and management.

Basic or detailed training around Lean and Six-Sigma tools is also offered for your employees in this offering.

Such an engagement model is typically based on an annual retainer ship, where a fixed number of hours per week/month/year are mutually decided.

Role based projects

In today’s times organizations may not want to hire a full-time employee for certain projects and/or roles.

Companies are now starting to save significant costs in terms of employee benefits by hiring consulting-based roles. Examples – i. You may have a team of QC experts within your organization but rather than hiring a full-time senior QC employee all you really need is someone to guide/mentor current team members and review or govern current projects. ii. Someone from your

Companies are now starting to save significant costs in terms of employee benefits by hiring consulting-based roles. Examples –

i. You may have a team of QC experts within your organization but rather than hiring a full-time senior QC employee all you really need is someone to guide/mentor current team members and review or govern current projects.

ii. Someone from your senior management office has recently resigned and you haven’t been able to back-fill the role with talent you want based on skills or budget. In such a case we can help you for a temporary time by filling in that role, not necessarily as technical expert, but more from a managerial/leadership/maintaining momentum around current projects.

Training

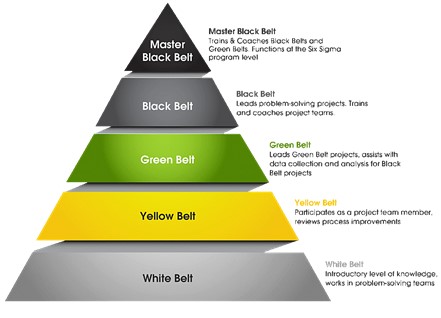

ARROWHEAD Consulting offers training programs that help organizations bolster project and problem management skills. These programs have curriculums based on world recognized standards of governance and certification in this domain. We offer levels of belt-based degrees in Lean Six-Sigma shown in pyramid.

Note: All other world recognized bodies charge significant renewal fees typically between $150 – $350 for every 2-3 years.

Highlights of training offered:

=> 3 attempts allowed; first successful attempt will disable exam link.

=> Exam format: open book; True/False; Multiple choice; time bound.

=> Certificate can be downloaded immediately upon successful attempt.

=> Each belt certification is perpetual and has ZERO renewal fees.

=>Tie-up with world’s top recognized certifying authority for Lean Six-Sigma based in USA.

=> Fees include training, content, exam, certificate.

=> Candidate will appear for online exam post training completion.

=> Candidate can appear for exam anytime within 12 months from date of registration.

=> If 3 attempts exhausted, then candidate to undergo training and exam again.

REQUEST A

CALL BACK

Please fill the form and click the submit button. We will get back to you in 1-2 business days.